The development of science and technology has produced many new materials, which not only help save costs and are environmentally friendly but also bring about a more sustainable construction structure.

Today, traditional building materials are gradually being replaced by new building materials, promising to bring a whole new look to the construction industry.

These types of materials make construction projects more sustainable, significantly saving construction costs, and shortening construction time. In addition, it also ensures high aesthetics and environmental friendliness.

Here are 10 new types of building materials commonly used in Vietnam in 2022.

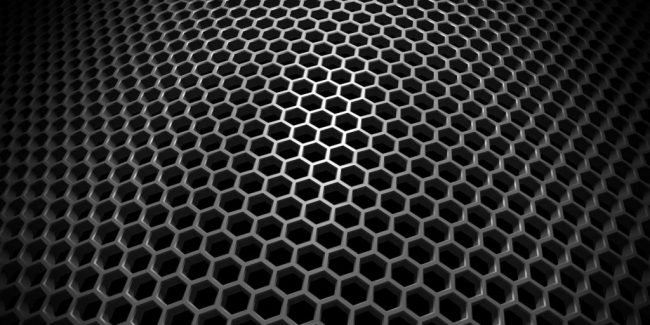

1. Graphene

Graphene is a new material, used more and more in the construction field because of its superior properties.

Graphene material is the name for flat sheets, made of carbon, consisting of a layer of carbon atoms arranged, and tightly bound together in a two-dimensional honeycomb lattice.

This material is extremely light, but its hardness is superior, far superior to diamond, and many times stronger than steel. Therefore, when combined with traditional building materials, it will help to have more sustainable and beautiful buildings.

Currently, the method to produce graphene is using the chemical vapor deposition technique.

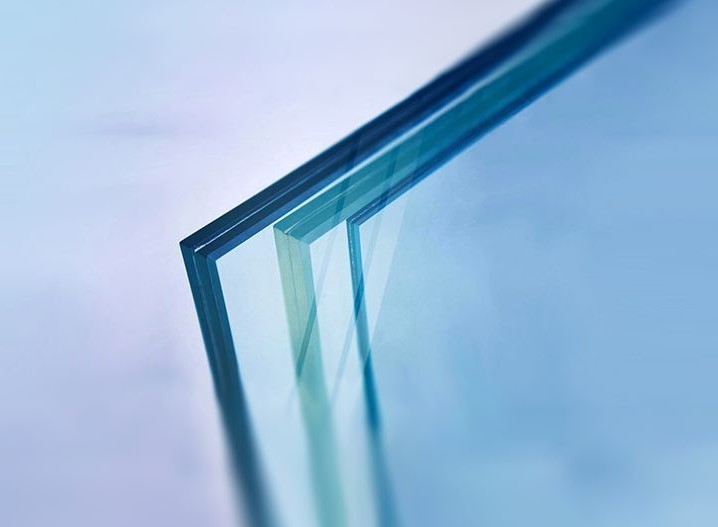

2. Energy-saving glass

Energy-saving glass is a new building material in Vietnam but has been used quite commonly in large and small projects around the world for a long time. This type of material offers many outstanding advantages compared to the old glass lines. Glass has a low emissivity coefficient, and a small coefficient of thermal conductivity, leading to a reduction in heat transfer between the inside and the outside environment through the glass wall system.

Currently, energy-saving glass commonly used in Vietnam has 2 types, Low E and Solar Control.

Glass Low – E

Low E glass short for Low Emissivity, is known for its slow heat emission feature. This type of glass is manufactured by coating an 8-layer nano-sized coating system on the surface of white glass blanks, in a high vacuum environment, in which silver metal plays a major role.

Low E glass products have an emissivity coefficient of 0.04 corresponding to the ability to reflect infrared rays up to 96%, thereby helping to stabilize the temperature inside the room and reduce heat loss to the outside.

Solar Control Glass

Solar Control glass is surface-machined with ultra-thin coatings that are composed of metals and metal oxides. As a result, this energy-saving glass is able to reflect most of the solar radiation, which increases the temperature inside the house.

In addition, using Solar Control glass also helps prevent ultraviolet rays harmful to human health, saving up to 51% on energy costs used to cool the inside of buildings.

The highlight of Solar Control glass is the ability to stand alone, without the need for canning but still ensuring functionality. Therefore, this type of glass can replace ordinary building glass materials in commercial and civil works.

3. Luminescent Cement

Blue and green luminescent cement are produced by mixing 4-5% optical fibers in a cement mixture. It is lighter in weight than base cement and has a uniform surface after concreting.

This type of cement can be used for highways, has the ability to absorb solar energy, and glow for up to 100 years.

Currently, luminescent cement products have been tested to build bathrooms and toilets in low-light buildings and have yielded positive results.

4. Self-healing concrete

Self-healing concrete (SHC) is a potential material for the future construction industry with the ability to self-heal cracks and durability for up to 50 years.

This type of concrete used in construction can help improve the durability of structures and reduce repair and maintenance costs, especially for large structures or underground works. Therefore, self-healing concrete is suitable for places with harsh environments such as coastlines, geothermal power plants, etc.

5. Green concrete

Green concrete materials are manufactured using conventional materials but partially replaced with suitable waste and recycled materials for efficiency, economy, and sustainability.

Specifically, green concrete is produced from raw materials such as fly ash, recycled concrete aggregates, and aluminum fibers. Accordingly, this new type of concrete also has a 30% increase in durability compared to normal concrete. In addition, using green concrete helps to increase the efficiency of use in buildings and structures; minimize the amount of cement in the production process.

6. Cooling brick

Cooling brick is a type of paving brick that is used quite commonly in projects with heat resistance needs.

This type of brick is made of a PU (Polyurethane) core and 2 layers of special cement. All brick materials have good insulation ability, with low thermal conductivity, so it helps to resist heat effectively.

Currently, cool bricks are produced in quite large sizes, the most popular are 1200x2240mm and 1200x600mm panels. The thickness of bricks has 4 types: 20mm, 30mm, 40mm, and 50mm. The heat resistance of bricks will increase with thickness.

The main function of sound insulation, reducing labor costs, and increasing useful area. Accordingly, cool bricks are used as thermal and sound insulation solutions for most items of a building such as walls, ceilings, and floors, walls…

7. Bricks from cigarette butts

Brick recycled from cigarette butts researched by RMIT University in Australia is gradually becoming a popular construction material today.

This type of building brick is made from cigarette butts and cigarette butts, so it is cheaper and uses less energy than traditional fired bricks. Accordingly, cigarette butts are mixed with traditional clay bricks, reducing the amount of energy required by 58%.

Bricks made from cigarette butts have better electrical insulation, which cuts down on heating and cooling costs in homes, and are easier to transport because bricks are lighter in weight than traditional bricks.

8. Carbon fiber balsa

In the past, balsa wood was a material known for its exceptional hardness. However, the cost of this type of wood is too high, making it difficult to apply widely.

Accordingly, carbon fiber balsa with a cheaper price along with the hardness, durability, and lightness of the material was created by scientists to replace balsa wood. At the same time, this new type of material also overcomes the problems that conventional wood structures exist such as uniformity, and inaccuracy.

Carbon fiber balsa has a cellular structure, which is minimized in weight thanks to the voids present in the structure. Besides, this material also has uniformity in surface and material.

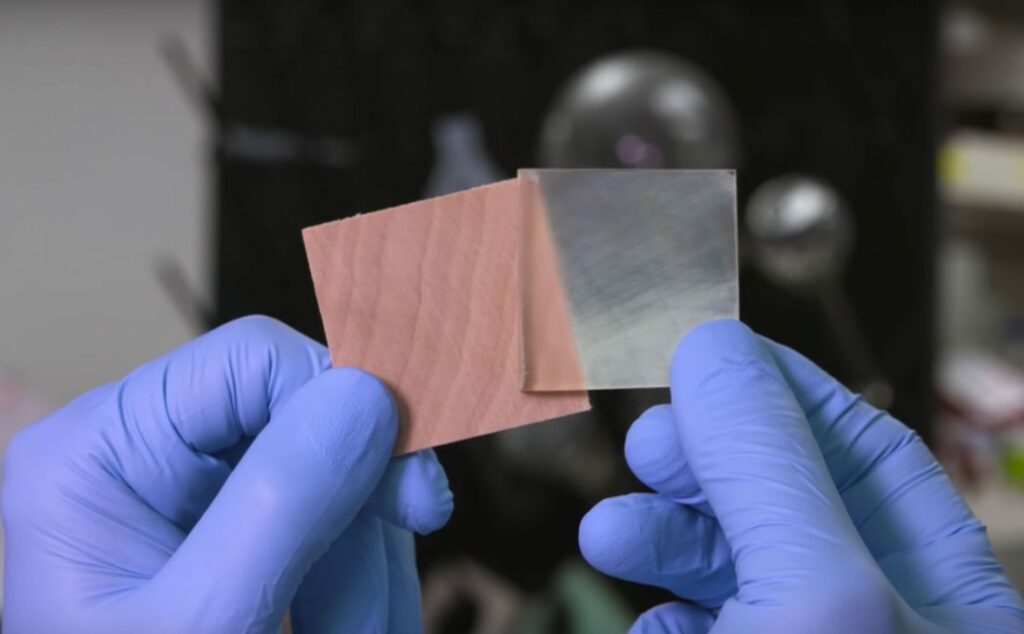

9. Transparent wood

Transparent wood, also known as invisible wood, is a new type of building material appearing in Vietnam. This material is made from a wick, a fast-growing tree. The wood is oxidized in a special bleach bath, then impregnated with a synthetic polymer.

Transparent wood products have similar properties to natural wood but are waterproof thanks to the polymer composition and are also not as fragile as ordinary glass because the internal cell structure helps to resist breakage.

In addition, the researchers confirmed that transparent wood will insulate five times more effectively than traditional glass if used as a window. The process of making new materials is also more environmentally friendly.

10. Nano Materials

Nanomaterials are a new type of material that has a structure of particles, fibers, tubes, and thin sheets. New nanomaterials that withstand intense pressure and compression.

In addition, Nanomaterial is also known to be a lightweight and durable material that is not inferior to materials with the same function.

In construction, Nanomaterials can be combined with reinforced concrete to create a material that can both withstand force and withstand extremely good compression.

The use of the latest building materials in construction is a breakthrough in recent years. With many outstanding advantages, they can replace traditional building materials such as iron and steel, cement, and brick… in the future.